Overview Of The Plan

In the intelligent transformation of mines, precise perception and global collaboration are key to breaking through the bottleneck of production safety. However, due to the extreme environmental constraints such as heavy dust and low illumination throughout the entire mining process, existing perception methods generally fail, and the data chain is disrupted, becoming the core bottleneck of intelligence. Kyle Optics, with its core technology of lidar 3D perception, integrates multiple sensors and intelligent algorithms to construct an intelligent perception solution covering the entire process of "exploration - mining - transportation - security - inspection" in mines. Through deep adaptation to technical scenarios, it achieves intelligent upgrades in key links, achieves full-process data connectivity and collaborative intelligence, significantly improves resource utilization efficiency and safety production levels, and provides a reproducible practical example for the intelligent deve

Application Scenarios

Paired with different hardware and software products, it can detect and measure multiple scenarios

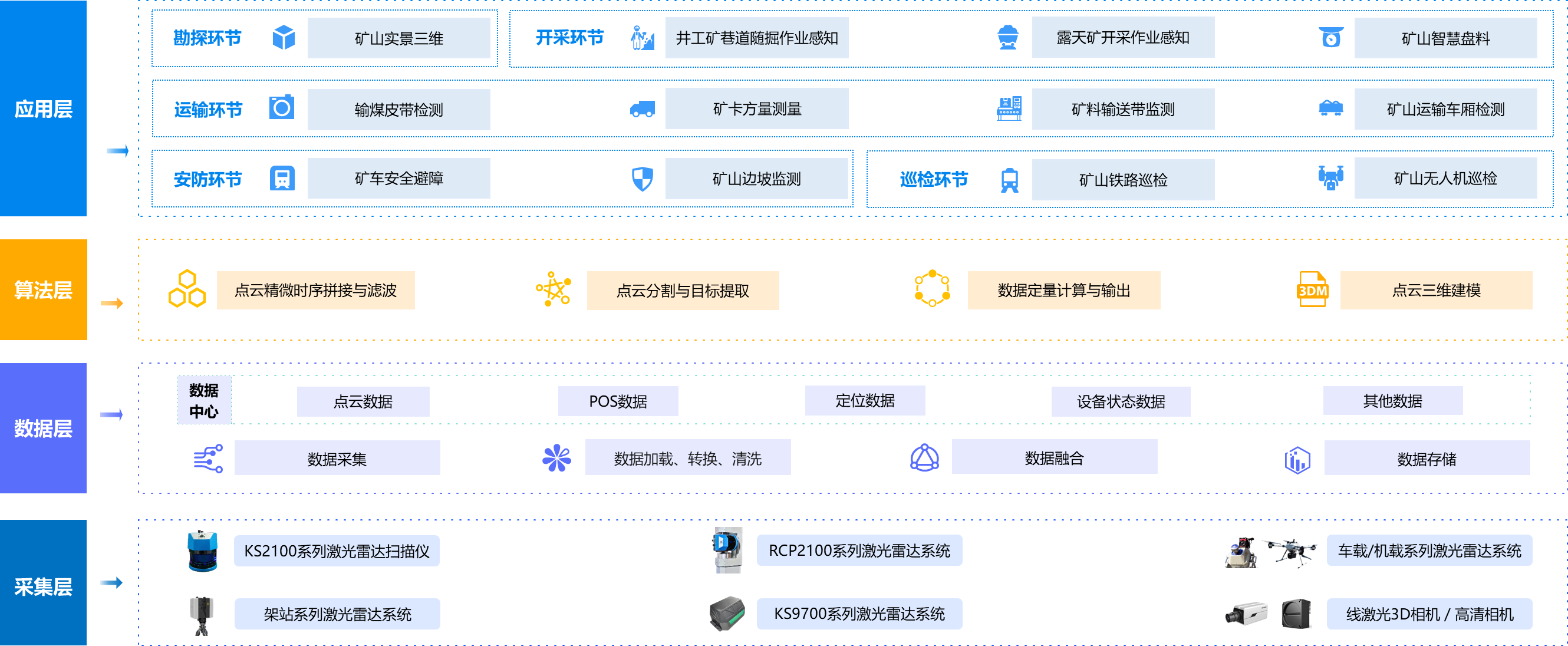

Scheme Architecture

Advantages Of The Plan

The three-dimensional perception accuracy reaches the millimeter level, with real-time response in the millisecond level, covering the entire mining process scenario.

Company Instance

The three-dimensional perception accuracy reaches the millimeter level, with real-time response in the millisecond level, covering the entire mining process scenario.

相关产品

The three-dimensional perception accuracy reaches the millimeter level, with real-time response in the millisecond level, covering the entire mining process scenario.

-

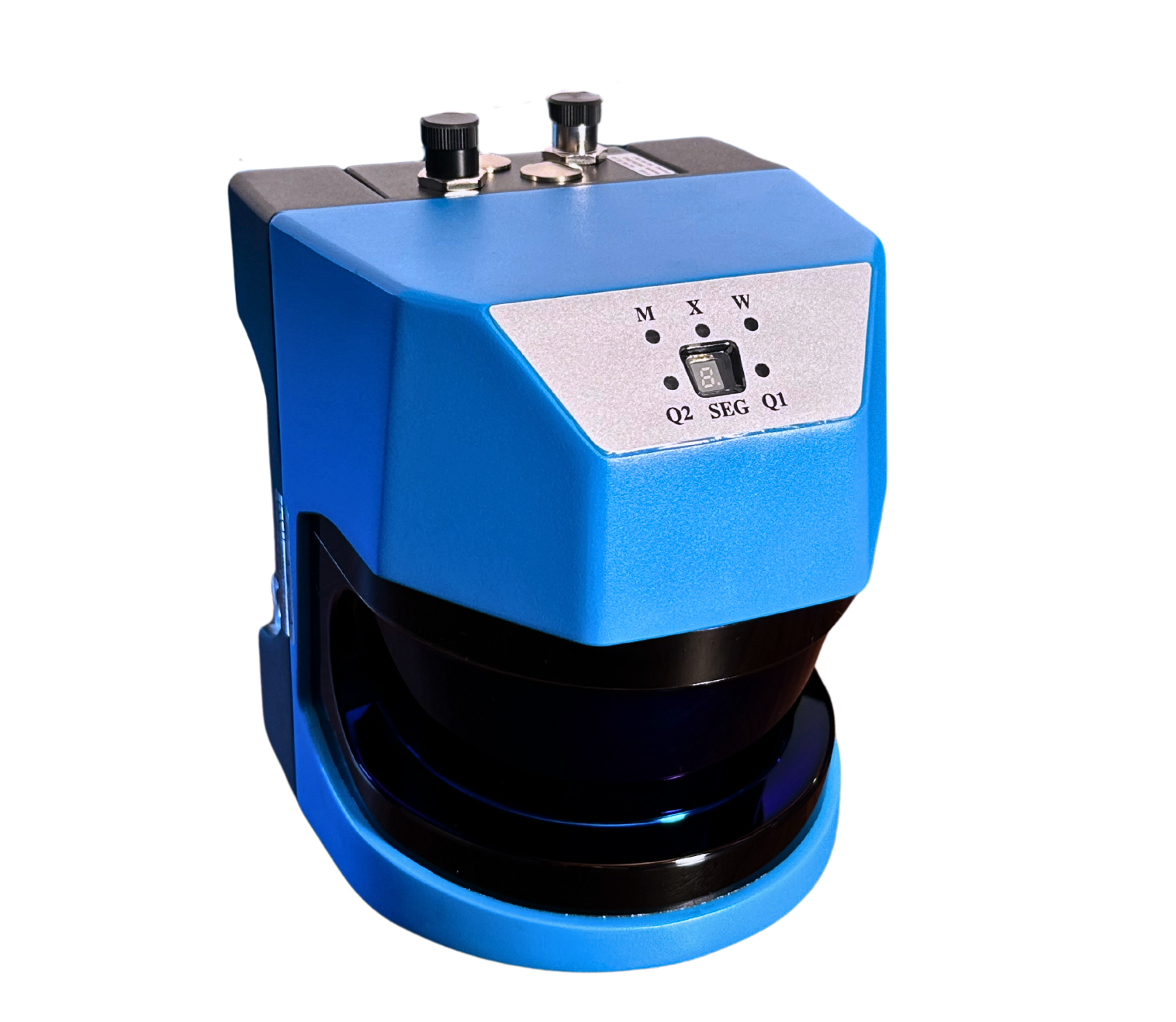

KS2100Series LiDAR

A high-performance industrial laser scanner that can work continuously and reliably for a long time, and can still clearly identify targets in complex weather environments such as rain, snow, and fog. It can be widely used in port equipment positioning, bulk cargo stacking volume measurement, unmanned vehicle navigation, regional protection, safety protection and other fields, covering industries such as thermal power, ports, metallurgy, cement, mining, and highways.

MORE

-

RCP2100三维激光雷达扫描仪

防雨、防尘、耐腐蚀,适应各种恶劣环境,在港口、工厂、电力、能源等行业已实现广泛应用。

MORE